Autonomous Marine Farming with Drones and Floating Robots

Autonomous Marine Systems in Aquaculture: Leveraging Drones and Floating Robots

The advancement of digital technologies over the past decade has ushered the aquaculture industry into a new era—one marked by the integration of autonomous and robotic marine systems. At the heart of this transformation lies machine autonomy in tasks related to sensing, monitoring, and management, powered by the convergence of artificial intelligence, the Internet of Things, and aquatic robotics. This innovative approach has significantly boosted production efficiency while addressing the challenges posed by limited manpower and the complexities of offshore operations. The application of machine learning algorithms for real-time data processing and environmental analysis enables more transparent strategic decision-making and allows for rapid responses to shifts in aquatic parameters such as temperature, salinity, and oxygen levels.

The marine environment, with its dynamic water currents and diverse ecosystems, presents considerable challenges in monitoring and managing aquaculture farms. Limited diver access to remote areas, safety risks in deep waters, and sudden changes in weather conditions undermine the effectiveness of traditional methods. Furthermore, biofouling and algae accumulation on nets can quickly jeopardize fish health, reduce yield, and drive up operational costs. Autonomous robots—such as floating systems equipped with real-time monitoring and net-cleaning capabilities—have emerged as a highly effective solution.

According to the Food and Agriculture Organization (FAO) 2024 report, global aquaculture production in 2022 reached 223.2 million tonnes, combining outputs from fisheries and aquaculture. Of this, 185.4 million tonnes were aquatic animals, and 37.8 million tonnes were seaweeds. Notably, aquaculture accounted for 51% of all aquatic animal production, surpassing wild catch for the first time—highlighting the growing significance of this industry in global food security.

Over the past two decades, the global per capita consumption of aquatic food has increased from 14.4 kilograms in 2000 to approximately 20.7 kilograms in 2022. It is projected to reach around 21.3 kilograms by 2032. This growth helps meet the rising global demand for marine protein but also underscores the urgent need for improved sustainability and minimized environmental impact. Automation in aquaculture operations offers more precise resource management while reducing feed and energy consumption.

– Daniela Rus, Director of MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL): “If you take a close look at any industry, you’ll see AI is reshaping the nature of work in that field.”

This perspective highlights the pivotal role of artificial intelligence in transforming industrial processes through increased automation and enhanced decision-making capabilities. It underscores the potential of combining deep learning algorithms with autonomous systems in aquaculture—bringing unprecedented accuracy to tasks such as feeding, biological monitoring, and disease control.

– Liu Jingkun, Associate Professor, China Agricultural University: “These are robotic tuna and robotic dolphins that we’ve designed.”

This achievement reflects how research teams, by simulating the biomechanics of aquatic species and equipping them with precise sensors, have developed reliable robotic models for monitoring and guiding aquaculture operations.

Despite significant progress, challenges remain—such as data integration, compliance with environmental standards, and the high initial costs of deploying autonomous systems. Nonetheless, the integration of cloud technology, IoT, and intelligent marine robotics opens up new possibilities for optimized cultivation models, enhanced productivity, and reduced bio-contamination risks. The remainder of this article will explore the core mechanisms through which autonomous drones and floating robots collect data and enable efficient aquaculture farm management.

Key Mechanisms of Autonomous Drones in Aquaculture Management

With the rapid expansion of marine aquaculture farms, there is an increasing need for accurate and cost-effective systems to continuously monitor environmental and biological conditions. Autonomous drone systems equipped with advanced imaging tools and water quality sensors enable the real-time tracking of both biological and physical parameters at scheduled intervals. By minimizing human intervention and improving responsiveness to environmental changes, this technology plays a vital role in enhancing the sustainability and productivity of aquaculture operations.

Numerous studies have highlighted drones as efficient alternatives to traditional aerial and marine inspection methods. Outfitted with multispectral sensors and high-resolution cameras, these drones can rapidly collect valuable data such as algae coverage percentage, water turbidity, and salinity levels. This information is transmitted in real time to cloud platforms, where it is processed using machine learning algorithms.

One of the major challenges lies in adapting computer vision algorithms to outdoor conditions and environmental noise caused by light reflections and wave movement. Research shows that lightweight neural networks like YOLOv8 maintain high detection accuracy while being executable on the drone’s onboard computers. This approach reduces detection and response time to under one second, greatly improving monitoring quality.

– Mikkel Pedersen, Founder of Probotic: “This isn’t a job for humans; it should be done by machines.”

This statement encapsulates the core philosophy behind the use of autonomous technologies in aquaculture: repetitive and physically demanding tasks such as net inspections and water condition monitoring require precision and consistency—qualities that autonomous systems are uniquely suited to deliver.

– Multispectral Imaging Systems for Water Quality Assessment

A key component of autonomous aquaculture drones is the use of multispectral and infrared cameras that can capture light reflections across different wavelengths. By analyzing these reflections, it becomes possible to estimate indicators such as algae density, organic matter accumulation, and dissolved oxygen quality. In a study by Pham and Han, the use of YOLOv8 for identifying fish farming cages and monitoring their biological parameters reported an accuracy of over 90%.

In these systems, drones automatically fly at a fixed altitude, capturing multispectral images at regular intervals. The data is then transmitted via a communication network to a central server where it is processed and used to generate a monitoring schedule map. This cycle of continuous environmental monitoring allows farm managers to implement preventive measures before issues arise.

– AI Algorithms for Real-Time Image Processing in Autonomous Flight

Another critical element in autonomous drone infrastructure is deep learning algorithms and neural networks that handle image processing with minimal human input. In many research projects, optimized versions of YOLO have been used for real-time detection of fish cages, fish counting, and identifying net damages. For instance, the implementation of YOLOv8 in aquatic environments has enabled the detection of over 200 cages in a single flight.

These algorithms, trained on real aquaculture imagery, have developed the ability to distinguish between relevant targets and irrelevant noise such as waves or suspended particles. Moreover, integrating machine vision models with path planning algorithms like Hybrid Path Planning (HPP) has enabled drones to cover all necessary areas with minimal energy use and along the shortest possible route. These optimizations not only reduce mission time but also play a key role in maximizing the productivity of aquaculture farms.

Ultimately, when combined with cloud infrastructure, autonomous drone systems provide end-to-end data management capabilities. Data is securely stored and visualized through specialized dashboards designed for analysts. This integrated approach represents a major step toward full digital transformation of the aquaculture value chain—from farm to table.

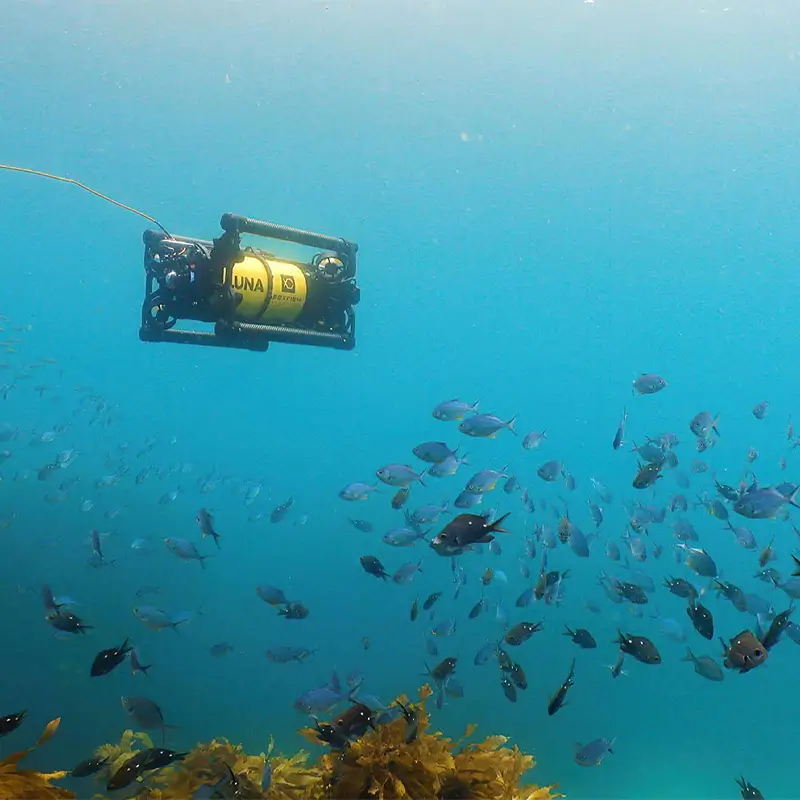

Autonomous Robots for Underwater Net Cleaning and Monitoring in Aquaculture

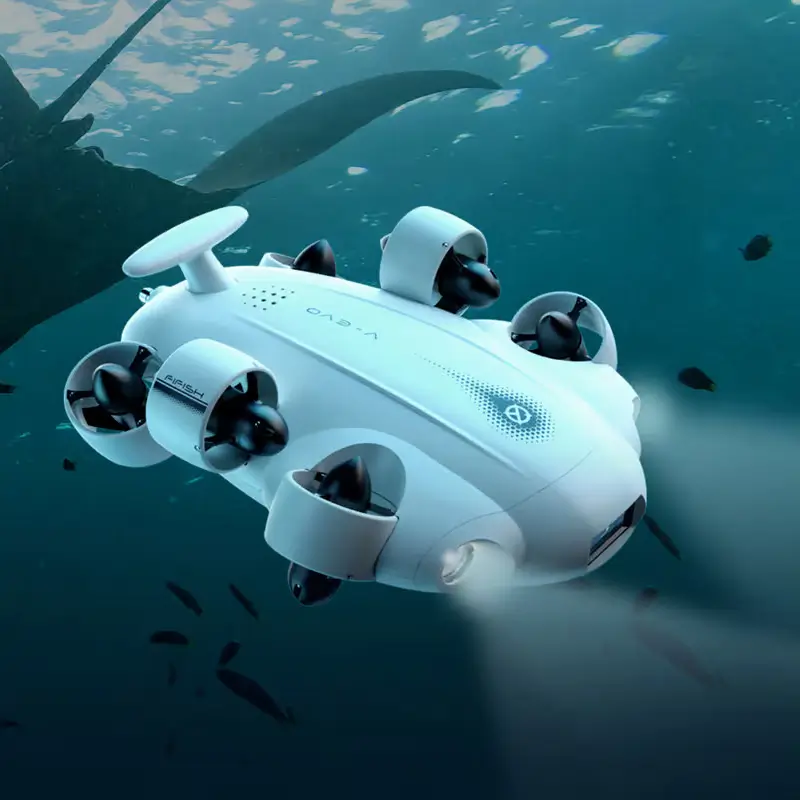

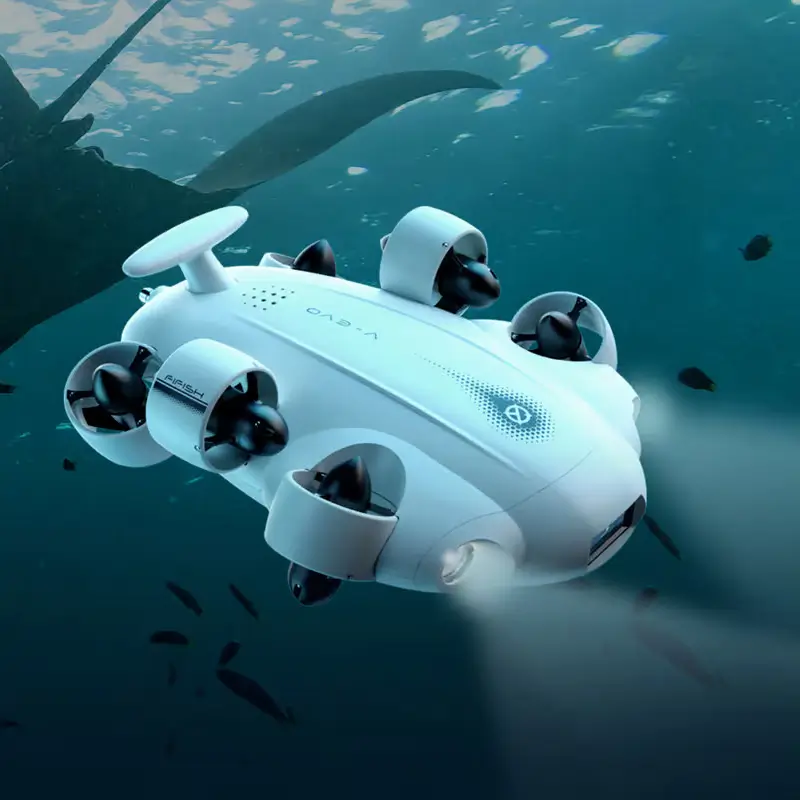

In aquaculture farms, the accumulation of algae and biological fouling on farming nets is a major cause of reduced water flow, which in turn limits gas exchange and fish feeding. Autonomous underwater robots, equipped with rotating brushes and suction systems, clean the nets regularly without the need for divers, eliminating the need to halt operations for manual maintenance. These systems move evenly across the net surfaces, continuously removing biofouling and minimizing the risk of disease among fish populations.

– Mechanical Tools for Net Cleaning

These tools primarily rely on rotating brushes or soft blades that remove algae growth from the net surface with controlled pressure. Some models also feature suction systems that collect the debris and transfer it into onboard storage tanks. The process includes automatic adjustments to parameters such as brush rotation speed and distance from the net, helping prevent damage to the net structure. In addition to extending the lifespan of the nets, this system has been shown to reduce skin diseases and fish stress while cutting premature net replacement costs by up to 20%.

– Monitoring Fish Health and Collecting Biological Data

Some floating robots combine cleaning tools with environmental sensors, enabling simultaneous measurement of water quality, temperature, salinity, and dissolved oxygen levels. Real-time data is transmitted to cloud platforms and analyzed using data processing algorithms. Technologies such as multi-beam sonar also allow for fish density tracking and average length measurement. These insights help optimize feeding strategies and can reduce feed consumption by up to 15%.

– Kana Upton, Biologist and Farm Manager at Aqua-Cage Fisheries: “We typically use Deep Trekker remotely operated submarines to inspect net cages and look for any holes, so we’re actually assessing the physical structure of the nets. It’s part of our routine maintenance and monitoring program, but also a requirement for the certification we hold.”

Kana Upton emphasizes the importance of maintaining net integrity, noting that holes or tears can not only lead to fish escapes but also allow predators to enter the cages. Regular use of underwater robots helps prevent losses and reduce the costs associated with emergency repairs.

Beyond cleaning and monitoring, autonomous robots can also remove dead fish from the cages. Equipped with suction systems or mechanical hooks, they lift carcasses to the surface, preventing their accumulation at the bottom of the net—a key factor in bacterial growth.

Alongside these benefits, the cost of acquiring and operating floating robots is an important consideration. Smaller models typically range from $10,000 to $50,000 depending on their sensing capabilities and cleaning mechanisms. Given the savings on diving operations and hard-to-reach repairs, return on investment is often achievable in less than two years.

Finally, integrating these robots with cloud systems and management dashboards enables scheduled maintenance planning and preventive repairs. While challenges such as tether cable management, battery charging, and operator training exist, they are quickly addressed through proper training and technical support, ensuring continuous and reliable operation.

Integrating Autonomous Drones and Underwater Robots in Hybrid Systems

Hybrid Aerial–Underwater Control Systems (HAUCS) are designed to provide integrated monitoring coverage across aquaculture farms. These systems utilize autonomous drones for surface-level data collection and underwater robots for deep-water parameter measurements. In practice, drones equipped with sensors for temperature, salinity, and dissolved oxygen perform real-time water quality mapping and transmit the data to cloud systems. Meanwhile, underwater robots use multibeam sonar and physico-chemical sensors to precisely monitor various depths. After processing by AI algorithms, this data feeds into managerial decision-making processes, enabling smart and adaptive planning.

Integrating data from diverse sources remains a significant challenge. The HAUCS cloud system, built on IoT architecture, establishes a secure and stable data gateway. Data collected by drones and robots is first processed at local nodes and then transmitted via secure MQTT protocols to a central server. This architecture ensures synchronized data updates at short intervals, minimizing reporting delays. Additionally, with distributed databases and edge computing algorithms in place, the system reduces cloud processing loads and ensures scalability.

– Coordinated Drone Routing Using the HPP Algorithm

The HAUCS Path Planning (HPP) algorithm is designed to minimize drone energy consumption and operational costs. In this method, the farm is divided into a series of sampling points, and the HPP algorithm, combining the Vehicle Routing Problem model with a Graph Attention Model, generates the most efficient route with minimal travel distance and fewest required charging stops. Performance comparisons with GLOP tools show that for farms with more than 200 tanks, HPP outperforms in both solution quality and execution speed.

The adoption of HPP has reduced the number of drones needed for full-farm coverage by up to 30%, while optimizing the energy consumption per drone by more than 25%. The algorithm can also factor in environmental conditions such as wind speed and rainfall, updating flight paths based on real-time weather forecasts. This capability allows farm managers to adjust drone flight schedules proactively and avoid system failures during adverse weather conditions.

– Cloud-Based Decision Support System Powered by AI

Data collected by the HAUCS system is transmitted to a decision support system (DSS), which uses deep learning algorithms to deliver predictive insights on water quality and fish health. Models based on Recurrent Neural Networks (RNN) and Long Short-Term Memory (LSTM) architectures are capable of forecasting oxygen depletion hours in advance and recommending actions such as adjusting aeration flow or adding liquid oxygen.

The system also detects early signs of disease by analyzing swimming behavior and fish density patterns. Using computer vision and image classification algorithms, it identifies unusual movements or changes in fish appearance and issues early warnings. In a pilot implementation, this technology enabled disease outbreaks to be predicted up to 72 hours earlier than traditional methods, reducing fish mortality by up to 18%.

Finally, the HAUCS management dashboard offers visual tools including heatmaps of water quality, parameter trend charts, and real-time reporting, allowing managers to make fast, informed decisions. The dashboard features a simple, customizable interface that lets users select key indicators and set alert preferences tailored to their farm’s needs. Integration with GIS and satellite mapping provides a comprehensive view of the farm environment, supporting strategic management and planning.

Sustainable Development Outlook and Forward-Thinking Solutions in Autonomous Marine Agriculture

With the relentless advancement of autonomous and robotic technologies, a new horizon has opened up for sustainable development in aquaculture farms. Today, Hybrid Aerial–Underwater Control Systems (HAUCS) not only enable real-time monitoring of water quality parameters, but also integrate data from drones and underwater robots to provide a comprehensive picture of the farm’s biological status. This approach has significantly improved the accuracy of environmental forecasting and empowered managers with rapid-response solutions to protect fish health.

The growing global demand for aquatic products, coupled with limited natural resources, highlights the need for cost-effective and scalable farming methods. Predictive algorithms, embedded in cloud-based decision support systems (DSS), combine LSTM and RNN models to forecast drops in oxygen levels or changes in salinity up to 48 hours in advance. This predictive power not only reduces environmental risks but also minimizes financial losses due to fish mortality.

Optimizing energy and resource consumption is another cornerstone of future strategies. The HPP routing algorithm, for instance, has reduced the number of drones required by up to 30% and improved energy efficiency by over 25%. By integrating weather forecasts, it charts safer and shorter routes for drones, helping prevent sudden system failures.

Meanwhile, edge computing and distributed databases allow large volumes of incoming data to be processed locally, sending only the analytical outcomes and alerts to the cloud. This architecture cuts communication costs, boosts scalability, and enables faster digital infrastructure deployment, especially in remote aquaculture farms.

In the long term, integrating blockchain technology into the supply chain can ensure transparency in tracking the origin and quality of aquatic products. Recording all autonomous operations, monitoring data, and water quality test results in a distributed ledger will significantly enhance consumer and stakeholder trust, helping build a secure and authentic ecosystem.

Beyond the technical aspects, attracting strategic investment and developing innovative financial models is essential for the successful deployment of autonomous systems. Holding groups like Vestra can facilitate capital inflow into digital aquaculture projects by introducing sustainability-linked securities and performance-based financial instruments, accelerating the technology development cycle.

– Final Thoughts and the Path Ahead

The evolution of autonomous marine agriculture relies heavily on the integration of drones, underwater robots, and cloud-based systems. With predictive algorithms and secure IoT architecture, it becomes possible to manage resources with precision, reduce reliance on centralized manpower, and enhance environmental sustainability. Moving forward, cross-disciplinary collaboration between robotics engineers, marine biologists, and financial strategists will be key to turning technical innovations into practical, real-world solutions.

– Antonella Antonucci, Aquaculture Researcher: “The simultaneous use of aerial and underwater solutions creates the foundation for managing the production chain with unprecedented accuracy.”

The convergence of cloud computing, artificial intelligence, and marine robotics not only enhances production efficiency but also lays the groundwork for developing new industry standards—standards that ensure environmental sustainability, aquatic animal welfare, and greater profitability. This outlook points toward higher productivity and stronger access to export markets, positioning aquaculture as a vital contributor to global food security.

Ultimately, unlocking the full potential of autonomous marine agriculture requires expanding broadband infrastructure along coastal areas, training personnel to maintain autonomous systems, and implementing supportive policy frameworks. With the collective commitment of developers, investors, and policymakers, we can shape a future where aquatic food production is both highly efficient and environmentally responsible—setting a benchmark for other sectors of agriculture to follow.